|

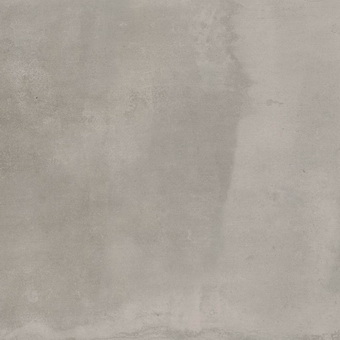

1.Polishing Checking Right after the tiles are polished, we arrange the positions to check the polishing effect of the tiles, to make sure every piece of tile is polished with the right angle and is fully polished. Unqualified tiles will be picked out and polished again, then lower the grade. |

|

|

2.Size checking We have special workers to measure the size of the tiles after the whole polishing process. Our workers will check the diagonal line and the edge. If the length deviation is more than 0.2%, the tile will be lowered the grade. |

|

|

3.Color Code Checking During the process of porcelain polished tiles, there will be a natural deviation of tile colors resulting from the slim difference of tile body. We arrange workers to sort the tiles to two or three color code, and then these tiles will be picked up differently. Of course, these tiles will be sold in different batches. |

|

|

4.Pinhole Checking During the production of one batch, we will pick up certain quantity of tiles at certain time, and check the pinhole of these tiles. If there is pinhole on the surface, we will adjust the polishing line as soon as possible in order to produce the best tiles. |

|

|

5.Broken Checking The last step of the production line is to pick up tiles and to check the corner broken. All the broken tiles will be taken out to a lower grade |

|